Radnor, Pennsylvania-based Aramsco was founded as a regional supplier of industrial safety products in 1966. In the six decades since, the company has grown to become the United States’ largest supplier of equipment and supplies to contractors in the restoration, remediation, cleaning, and environmental cleanup sectors.

Today, the company offers a portfolio of over 40,000 products and operates some 70 branch locations across North America. It has also expanded beyond distributing products, now providing additional services like training and education, equipment rentals, equipment repair, and equipment financing.

As its business expanded, the company faced the challenge of managing its diverse inventory across multiple locations. In particular, it struggled with inaccurate product data and with manual receiving processes that were proving to be a drag on warehouse efficiency and were driving up shipping costs.

In particular, Aramsco struggled with the following aspects of its logistics operations:

- Estimating shipping costs: Aramsco lacked accurate weight and dimensional data on its inventory, leading to difficulties in providing accurate shipping quotes.

- Inefficient space utilization: With plans to consolidate branches and establish more distribution centers, Aramsco needed data on product dimensions to improve warehouse space utilization.

- Data-entry errors: The process of manually measuring and recording product dimensions was time-consuming and prone to human error.

- Integration of 40,000+ stock-keeping units (SKUs): As Aramsco acquired new companies and expanded into new industries, it faced the challenge of quickly and accurately populating new product data into its inventory system.

- Missing dimensional data: With multiple branches nationwide, maintaining consistency in inventory management practices was becoming increasingly difficult.

“We have 60+ sites across the country, many of which have unique SKUs, and for several years, we obtained the weight/dims manually, which we got very good at, but there was always the concern for accuracy due to the manual process,” Ronnie Bobo, operations administrator at Aramsco, said in a release.

TO BE PRECISE …

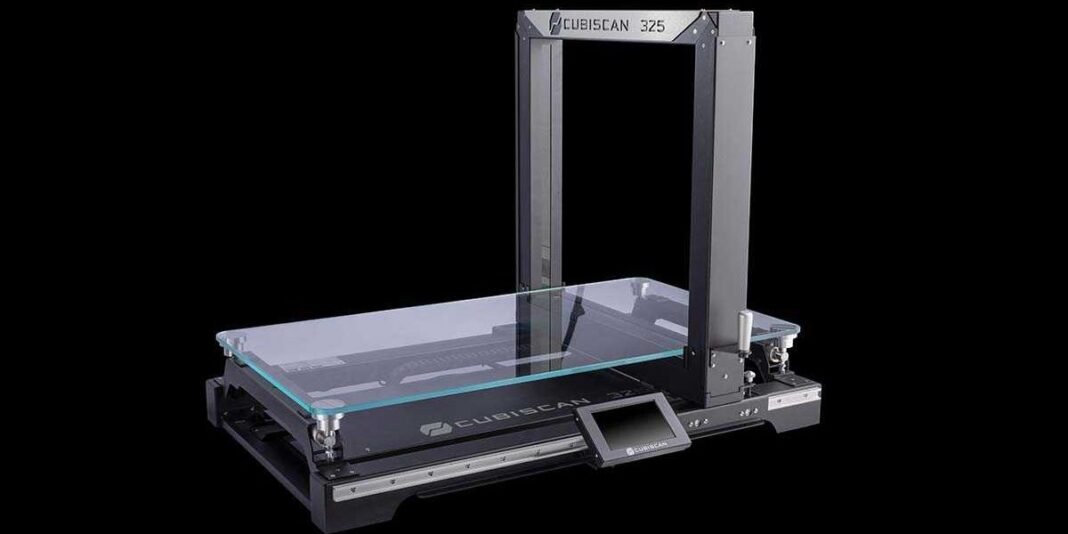

The company’s search for a solution led it to Cubiscan, a Farmington, Utah-based provider of parcel dimensioning and weighing systems for warehousing and shipping operations. After looking at its options, Aramsco chose the Cubiscan 325, a static weighing and dimensioning system that’s designed to measure the length, width, height, and weight of medium-sized items. The model uses infrared LED technology to measure those goods in 1-millimeter increments.

According to Aramsco, the Cubiscan 325 has provided it with accurate weight and dimensional data on 95% of the items in its inventory, which has allowed it to cut dimensional shipping costs, eliminate data-entry errors, and reduce unused storage space to the point where it was able to consolidate its Pennsylvania and New Jersey facilities into a single site. The results have been equally impressive on the operations side: After implementing the Cubiscan 325, Aramsco saw a 33% increase in productivity and a 100% reduction in dim-weight shipping corrections. On top of that, the company is now able to receive and record more than 1,000 SKUs per week.

“After finally convincing our executive team of the value of purchasing the Cubiscan 325, we’ve seen a great improvement in the efficiency of the dims,” Bobo said. “Our efficiency has improved by over 25% and, though we can’t measure the accuracy improvement, it’s good to know the data we’re currently feeding into the system is 100% accurate. We are consolidating warehouses into distribution centers and plan to purchase several more Cubiscan 325 units.”