Vertical farming company OnePointOne took a giant leap into the future of agriculture earlier this year, thanks in large part to its partnership with automated warehouse equipment specialist AutoStore. The companies joined forces to apply AutoStore’s robotic automated storage and retrieval system (AS/RS) technology to the growing of fresh, leafy greens—indoors, in optimal conditions to yield high volumes of produce.

The result, a system called “Opollo Farm,” combines AutoStore’s modular robotic equipment with OnePointOne’s plant-production technology to overcome the cost and scalability challenges of vertical farming—a capital-intensive industry that requires the development of both innovative farming techniques and robotic capabilities that allow high-density growing to support rising demand for local produce. The partnership eliminates part of that technology burden, creating a win for both companies—AutoStore is venturing beyond warehousing into a new industry, and OnePointOne can focus on its long-term goal to provide sustainable, locally grown produce to people around the world.

The system is already up and running, supplying leafy greens to Whole Foods Market stores throughout Phoenix under the Willo brand. The greens, which have been offered in the Phoenix area since this spring, will soon be available at the retailer’s locations across Arizona, according to the companies.

PICKING UP THE PACE

Autostore

OnePointOne’s founding mission was to feed the 1.1 billion people around the world who were malnourished at the start of the 21st century—a number that is even higher today, according to CEO Sam Bertram, who launched the company with his brother, Chief Technology Officer John Bertram, in 2017. Eight years and $75 million in funding later, OnePointOne has taken a giant step in that direction with the Arizona Whole Foods deal.

It’s a milestone the company might not have reached so quickly on its own. As Sam Bertram explains, OnePointOne had developed its own patented robotics system to operate the vertical farm—which is a fully automated operation that combines robotics, lighting, irrigation, and climate control (heating, ventilation, and air conditioning) for growing produce indoors. But scaling that technology to support the company’s growth promised to be an uphill battle.

“[Our system] had nowhere near the scale or reliability of AutoStore,” Bertram explains, noting that the two companies had been following each other’s progress in their respective fields for years before deciding to work together. “So we put our ego in our back pocket and said, ‘Let’s see if we can turn the AutoStore system into a farm.’”

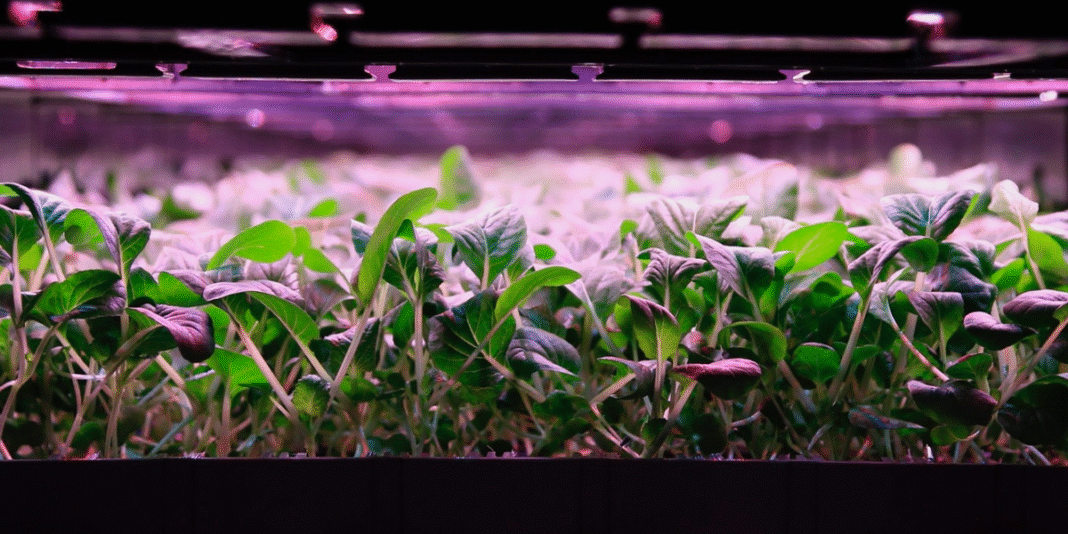

That’s exactly what they’ve done. In a warehouse outside of Phoenix, Opollo Farm is growing salad greens inside AutoStore’s robot-powered bins—greens that are harvest-ready within 15 days, which is about half the time required with traditional farming. The vertical farm features:

- A hydroponic growing system: Plants are grown in bins within a closed-loop system where water is recirculated, reducing water use by up to 95%.

- High-density cultivation: Plants are grown at the highest possible density, allowing farms to be built inside existing distribution centers.

- Automated plant movement: Powered by AutoStore’s cube storage system, plants move autonomously throughout the facility, entering and exiting the storage grid through a single port—reducing the need for a large on-site workforce.

- Scalable architecture: Whether operating at small or large scale, Opollo Farm delivers consistent performance and can be expanded seamlessly to meet growing demand.

- A controlled environment: The fully enclosed system protects crops from pests and contamination, eliminating the need for pesticides.

- A local supply chain: Proximity to urban centers allows for shorter supply chains and reduced transportation emissions.

OnePointOne’s suburban Phoenix farm supplies the greens to Whole Foods’ local DC, which then distributes them to retail outlets. Bertram says the long-term plan is for retailers to purchase the vertical farms and operate them inside their own DCs—eliminating the logistics involved in transporting the produce from farm to DC, which the companies say would shorten the supply chain by more than 90%. It would also allow for year-round growing of an increasing array of produce: Opollo Farm plans to expand its production of greens to include basil, microgreens, and other herbs before moving on to fruits, including strawberries, blackberries, and raspberries.

MAKING IT WORK

Opollo Farm represents an opportunity for AutoStore to showcase the system’s flexibility and versatility, according to Margherita Carrozzo, the company’s director of product strategy and operations. She says minimal modifications were required to adapt the system for vertical farming. The main difference, she says, is in the system’s bins: Because plants are grown in trays inside the bins, the bins’ sides have been cut out so the plants can receive water and light.

“Our technology has solved a problem in a different industry—but the system is very similar to what we use today in warehousing,” Carrozzo explains. “The core features of AutoStore that have [led to our] success in warehousing are also very relevant in vertical farming: density and reliability.”

The system’s density not only allows for the growing of plants in close proximity to consumers but also helps optimize energy use in the energy-intensive vertical farming industry.

“And [then there’s] the system’s reliability—an automated vertical farm [runs on] a technology that you don’t need to babysit,” Carrozzo adds, emphasizing AutoStore’s experience and longevity in the industry. The company has installed more than 1,700 systems in 60 countries around the world. “Vertical farming is missing [this] stable robotics technology.”

Carrozzo says she looks forward to the next steps in the partnership. The Opollo Farm in Phoenix measures 1,000 square feet and utilizes approximately 1,000 bins, leaving plenty of room for growth.

“We can deliver at tens of thousands of bins—and even more,” she says. “We are excited about exploring the future.”