It is not unexpected that the transition to electric trucks could entail challenges. That one of the parts that would cause problems would be the … ‘traditional’ 24V battery, that might be. We outline what is going on and how constructors deal with it.

VPD, based in Zellik, has a dozen electric trucks in its park, including a Volta Zero. An instructive experience for Fleet Manager Koen Moyson is also an unexpected problem: the 24V low -voltage battery discharges in the event of a longer standstill, which causes pannes. According to Moyson, that would be due to, among other things, the cooling of the battery. VPD tries to prevent it by starting regularly and driving as much as possible, which of course has an operational impact … especially if the park contained many EVs that should be followed in this way.

In the car world, where electric vehicles are now more established, the problem occurs in an exceptional situation. There it is mainly due to a combination of a smaller 12V battery (that is why the problem occurs more with EVs than with cars with combustion engines) and more energy consumers such as larger digital screens, connected modules and control systems that are also regularly active in the event of a standstill. However, software keeps an eye to try to prevent the 12V battery discharging too strongly, making the problem relatively rare in cars.

What do the truck constructors say?

According to a response from most truck brands, the battery cooling cited at VPD is not an issue immediately. The cooling/heating system Put power from the high-voltage batteries, but the cooling water pump can be driven by the 24V battery. Since when the truck is plugged into the charging station or with an enabled contact, it is charged via a DC/DC inverter through the high -voltage battery, the best ways to avoid problems or hanging on the charging station. At Volvo Group it sounds that in that case the charging station must have the right settings to ‘maintain’ the voltage of the high -voltage batteries. If the truck is not charged for more than a week (for example, when repairs or work), the brand recommends that you disconnect the 24V batteries from the beginning.

With Scania, the cooling and heating system of the high-voltage battery is activated when the electric powertrain is switched on and at those times (and during charging) the DC/DC inverter ensures that the voltage of the 24V batteries stays up to date. Mercedes-Benz Trucks, which indicates that the 24V system only feeds the on-board electronics and communication functionalities, devotes a chapter to guidelines for longer downtime periods in the manual of its electrical trucks. In addition to periodically switching on the vehicle and plugging in to a charging station with a slow charging program during longer standstill, it is also recommended, for example, to set a departure time so that the system can pre -condition the battery with power from the charging station. Even with Man, it sounds that the system continuously checks and will charge the charging state of the 24V batteries if necessary, although the vehicle must of course hang on the charging station.

More active solutions

DAF Trucks, on the other hand, limits the 24V consumption in the event of a standstill to ensure that the battery is less empty. With the lighter low -voltage batteries, a limitation of the rest current to 100 mA applies, with heavier to 250 mA. DAF also included that consumption restriction in the construction guidelines, so that the maximum values are also respected there.

Iveco focuses on a revision of the management system of its electric vehicles. They have been carrying out a system check every 5 hours, where the 24V battery can get exhausted in the event of a long standstill. In the future, however, the low -voltage battery will also be charged by the high -voltage battery when the contact is not enabled and the vehicle is not hanging on the charging station. The condition is that the loading level of the latter does not dive below 15%. An example to follow?

Solar panels?

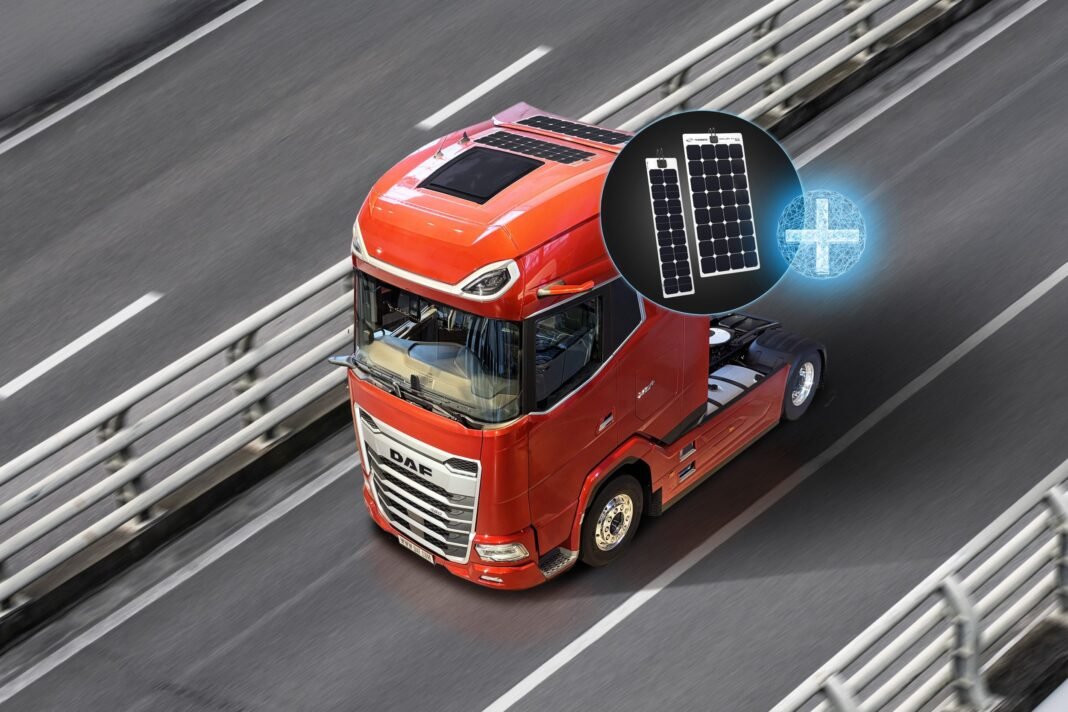

If a truck cannot linger on the charger, then solar panels could bring relief, for the 24V low -voltage battery anyway. Solar panels are currently sometimes used for cooling applications from trailers, but Paccar Parts now also offers them to charge the 24V batteries of trucks. The company mainly praises them because of comfort gadgets such as a television, coffee machine or microwave that taxes the battery, but it could also be a solution to avoid problems with the low -voltage battery of electric trucks in the event of a longer standstill.