Trelleborg e-mobility solutions were recently on full display at The Battery Show Europe. The company said it debuted several products aimed at supporting the fast-growing electric vehicle (EV) market.

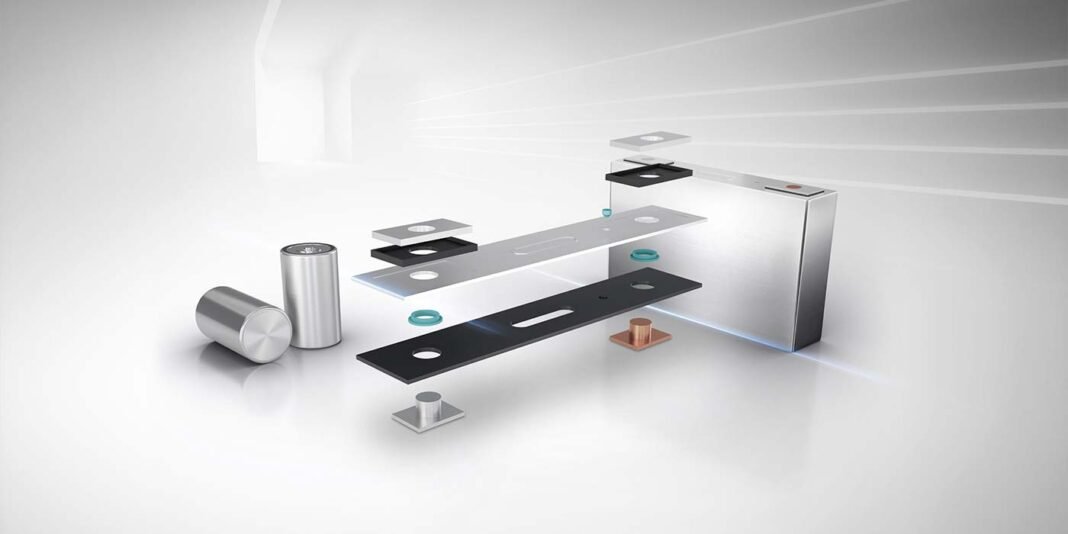

The centerpiece of Trelleborg’s display was its new CellXPro material range, designed specifically for sealing EV battery cells. This portfolio includes compounds based on ethylene propylene diene monomer (EPDM), fluoropolymer (FKM), and perfluoroalkoxy (PFA) compounds. Each material is formulated to enhance battery performance by increasing efficiency, extending range, accelerating charge times, and improving sustainability, Trelleborg said.

These compounds meet high operational demands and show strong chemical compatibility, the company said. CellXPro prevents damaging chemical interactions between electrolyte fluids and sealing materials—an issue that can affect battery performance and lifespan.

“The CellXPro portfolio leverages Trelleborg’s extensive experience supporting battery cell manufacturers in the specifications and testing of sealing materials specifically for EV applications,” said Axel Weimann, Director Global Segment Director for Automotive. “Its launch at The Battery Show positions Trelleborg as the sealing partner of choice for battery manufacturers. It enables them to select the right materials with confidence.”

Trelleborg E-mobility Solutions Include Thermoplastic Insulators, Radial Shaft Seal and Laminate

Alongside CellXPro, Trelleborg presented cell thermoplastic insulators. These are available as standalone components or integrated multicomponent parts. The multicomponent design combines an elastomer seal with a plastic insulator, reducing part count and offering both electrical isolation and sealing in one unit.

Trelleborg also highlighted the Stefa HiSpin EV40, a radial shaft seal built for modern EV motors. This elastomer seal is optimized for high-speed operation and low friction, enabling greater powertrain efficiency.

HiSpin EV40 uses Trelleborg’s proprietary Phase-Shifted-Wave (PSW) technology, which actively pumps lubricant back to the oil side during shaft rotation. This design maintains a reliable seal and reduces energy loss—even in lubricated systems, according to Trelleborg.

Trelleborg rounded out its offerings with the Rubore Washer, a three-layer laminate that seals and protects electrical systems from moisture and corrosion. It features rubber vulcanized to both sides of a metal core, creating a robust seal, even on scratched or uneven surfaces.

Rubore Washers are available in a variety of diameters, metals, designs, and thicknesses. The adaptive rubber layers ensure consistent sealing performance across a wide range of surfaces and applications, Trelleborg said.